INJECTION DEP

The purpose of our INJECTION DEP is to produce high-quality injection glasses.

MOULDING CENTER

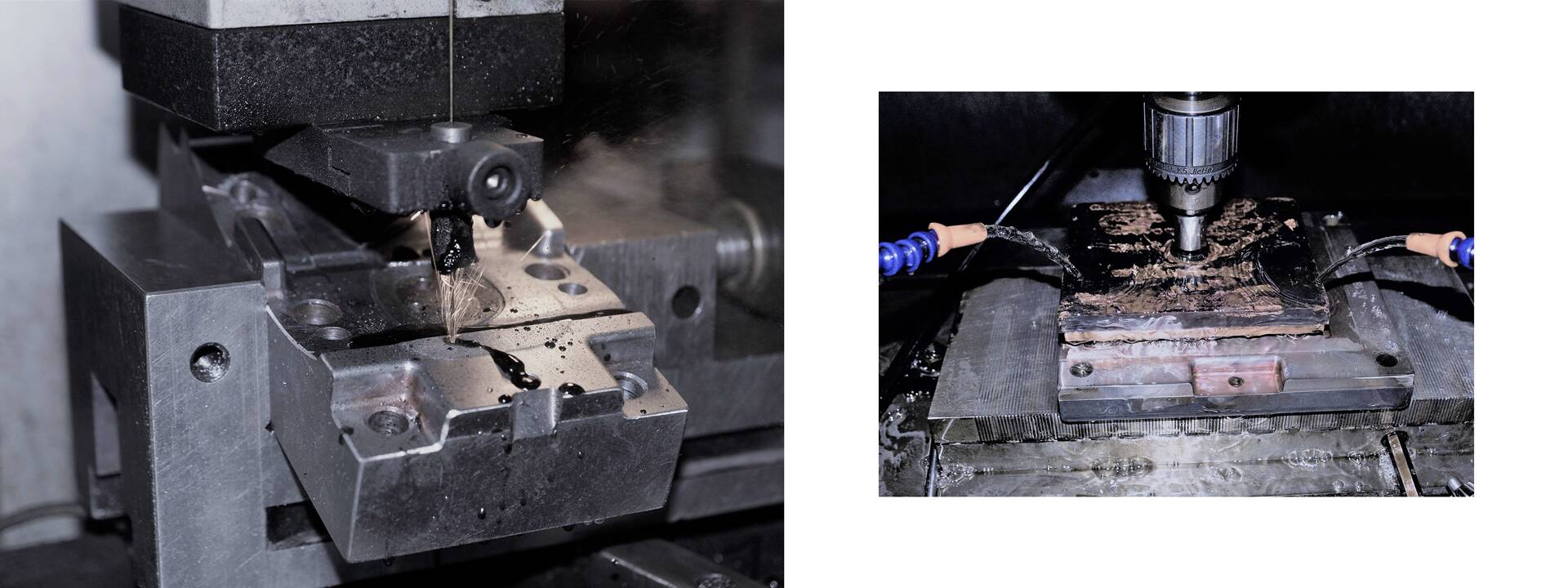

Making moulds is the first and most important process. We use advanced manufacturing technology to achieve the precision of the moulds.

INJECTION DEVICES

Injection eyewear frame starts at our moulding center.Every injection frame mould is made in house, where our design team and engineer team

would communicate with moulding team together about the detail data of frame and make sure the moulds they made are correct.

ROBOTIC ARM AUTOMATIC PRODUCTION

COATING

After the frame injection, we do the frame coating in house. And for some special coating, we have to make special mould to support coating.

Our QC Dep will cooperate with each other during these processes to ensure the high quality of the final product.

TUMBLING-POLISHING-PARTS INSPECTION

There are many other processes in our injection workshop.

If you want to know more, we welcome you to visit the factory.

Please contact us.

back to top

back to top